Sunny's blog

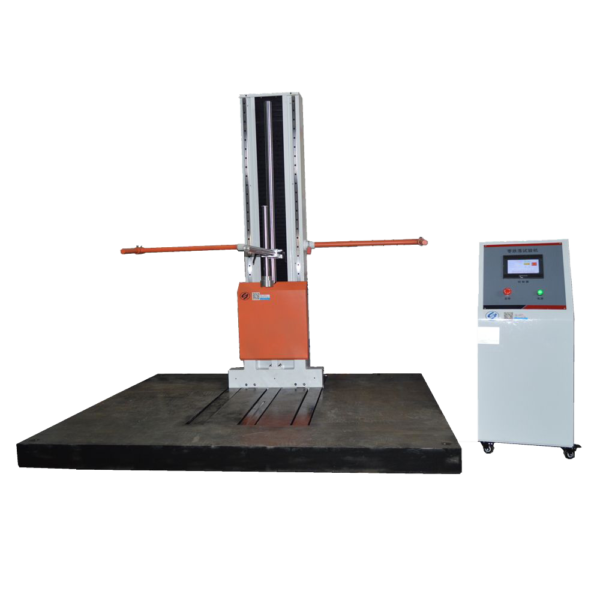

A drop test machine

serves a crucial role in assessing the durability of product packaging and

determining the impact resistance of items during transportation and handling.

This specialized equipment, known as a drop tester, is instrumental in subjecting

specimens to controlled drop tests to simulate real-world scenarios and

evaluate their structural integrity.

The primary

objective of using drop testers is to mimic the effects of accidental drops on

products, thereby gauging their ability to withstand impact forces. By

maintaining the orientation of the specimen during the drop and closely

analyzing the subsequent damage, manufacturers can gain valuable insights into

the performance and durability of their products.

Moreover, drop

testers find applications across a wide range of industries beyond electronics

and electrical equipment. They play a vital role in conducting drop tests for

diverse sectors such as medicine, food, and pharmaceuticals, where the safe

transportation of fragile or sensitive items is paramount.

For more than 23

years, Linkotest has been a trusted provider of high-quality mechanical drop

testers tailored to the needs of the drop test industry. Their extensive range

of offers includes mobile product drop testers, rotating drum testers, package

drop testers, and specialized testers for large items. This longstanding

commitment to delivering reliable testing solutions underscores Linkotest's

reputation as a leading player in the field.

In

conclusion, drop test machines are indispensable tools for manufacturers

seeking to ensure the robustness and resilience of their products under

real-world conditions. Linkotest's comprehensive range of drop testers caters

to a diverse set of industries and stands as a testament to their expertise and

dedication in serving the drop test industry for over two decades.

In the realm of

industrial safety, guardrail manufacturers stand as crucial protective devices

that play a pivotal role in averting potential damage resulting from vehicle

collisions within factory settings. Manufacturing plants, often bustling with

forklifts, AGVs, and various other vehicles, are prone to accidents that could

lead to severe consequences such as injuries to workers and damage to

production equipment. Considering this, the significance of high-quality

guardrails cannot be overstated.

As we delve into the landscape of guardrail

manufacturing, it becomes imperative to highlight the top 15 guardrail

manufacturers of 2023. These industry leaders have demonstrated a commitment to

excellence in producing reliable and effective guardrail solutions that enhance

workplace safety and mitigate the risks associated with industrial operations.

Company

A: Renowned for its innovative approach to guardrail design and engineering,

Company A has established itself as a frontrunner in the industry, offering a

diverse range of high-quality guardrail systems tailored to meet the specific

needs of different manufacturing environments.

Company

B: With a focus on durability and reliability, Company B has earned a

reputation for delivering robust guardrail solutions that provide superior

protection against vehicle collisions, ensuring the safety of workers and

equipment within factory premises.

Company

C: Known for its cutting-edge technology and advanced safety features, Company

C excels in designing state-of-the-art guardrail systems that offer enhanced

protection and peace of mind to manufacturing facilities across the globe.

Company

D: A trusted name in the realm of industrial safety, Company D prides itself on

manufacturing guardrails that combine functionality with aesthetics, creating a

seamless blend of form and function that elevates the safety standards of any

factory setting.

Company

E: Specializing in customizable guardrail solutions, Company E caters to the

unique requirements of diverse manufacturing plants, providing tailored safety

solutions that address specific challenges and hazards inherent to different

industrial environments.

Company

F: With a focus on sustainability and eco-friendliness, Company F stands out

for its environmentally conscious approach to guardrail manufacturing, offering

greener alternatives that promote safety without compromising quality.

Company

G: Leveraging years of experience and expertise, Company G has earned a

reputation for excellence in producing cost-effective guardrail solutions that

deliver exceptional value and performance, making safety accessible to

businesses of all sizes.

Company

H: Committed to continuous innovation and improvement, Company H leads the way

in developing cutting-edge guardrail technologies that set new standards for

safety and reliability in the industrial sector.

Company

I: Renowned for its customer-centric approach and dedication to service

excellence, Company I places a strong emphasis on building lasting

relationships with clients and ensuring their satisfaction through top-notch

guardrail solutions and support services.

Company

J: Embracing a culture of safety and quality, Company J prioritizes the

well-being of workers and the integrity of production processes, offering

guardrail systems that reflect a deep commitment to upholding the highest

standards of industrial safety.

Company

K: With a focus on versatility and adaptability, Company K excels in designing

modular guardrail solutions that can be easily customized and reconfigured to

meet evolving safety needs within dynamic manufacturing environments.

Company

L: Setting benchmarks for performance and reliability, Company L is renowned

for its durable and impact-resistant guardrail systems that provide

long-lasting protection against vehicle collisions, ensuring the longevity of

factory assets and the well-being of personnel.

In conclusion, the realm of flexible guardrail manufacturer is populated by a diverse array of industry leaders who are dedicated to advancing safety standards and protecting lives within industrial settings. By investing in high-quality guardrail solutions from these top manufacturers, businesses can fortify their safety protocols, mitigate the risks of accidents, and foster a culture of workplace well-being that is essential for sustained success in the manufacturing sector.

bollard manufacturer also referred to as car stops, represent a crucial component of

urban infrastructure, serving as physical barriers to enhance safety and manage

traffic flow. These sturdy, cylindrical columns are strategically placed in

roadways, typically at intersections, crosswalks, and other critical points, to

prevent accidents and protect pedestrians from potential harm. The primary

purpose of bollards is to deter vehicles from encroaching onto sidewalks or

pedestrian areas, thereby reducing the risk of collisions and ensuring

pedestrian safety.

In

the realm of urban planning and safety measures, bollards play a significant

role in creating secure and organized urban environments. By delineating spaces

and guiding traffic, these unassuming structures contribute to the overall

safety and functionality of public spaces. Their simple yet effective design

allows them to blend seamlessly into the urban landscape while providing

essential protection against vehicular intrusion.

Given

the importance of bollards in safeguarding public spaces, the selection of a

reliable and reputable manufacturer becomes paramount. In the rapidly evolving

landscape of bollard production, identifying the top manufacturers is crucial

for ensuring quality, durability, and adherence to safety standards. As such, a

comprehensive guide to the leading bollard manufacturers in 2023 is essential

for urban planners, architects, and safety professionals Company T

Each

of these manufacturers has demonstrated a commitment to excellence in bollard

design and production, offering a range of products to suit various urban

contexts and safety requirements. From traditional steel bollards to innovative

retractable models, these companies represent the forefront of bollard

manufacturing, setting the standard for quality and reliability in the

industry.

As

urban spaces continue to evolve and face new challenges, the role of bollards

as essential safety features will only grow in importance. By choosing products

from reputable manufacturers, urban planners and safety professionals can

ensure the effectiveness and longevity of bollards in safeguarding public

spaces and enhancing the overall urban experience. With the guidance provided

in this article, stakeholders can make informed decisions when selecting Bollard Supplier, thereby contributing to safer, more secure urban environments

for all.

Bollards, also known as car

stops, are a type of bay that is defined as a “fence or barrier in the

roadway.” They are usually shaped like cylindrical columns and installed

perpendicular to the ground. Bollards are usually installed at intersections,

crosswalk connections, or intersection openings to prevent casualties. Install

bollards to prevent vehicles from driving onto the sidewalk in the unlikely

event that they do. In the previous article, we mentioned a lot of knowledge

about bollards. So, in today’s guide, we will educate you on the top twenty

bollard manufacturers in 2023. After reading this article, you can make a

choice based on your actual situation. Read on to learn more.

Security barrier manufacturers play a crucial

role in maintaining a secure environment in areas where hazards are prevalent,

ensuring the safety of vehicles, goods, and individuals. Whether on the road or

within industrial settings, these protective measures are essential for

preventing accidents and minimizing risks. Selecting a reliable safety barrier

product is paramount, and this choice is heavily influenced by the

manufacturer. In this guide, we will highlight ten reputable security barrier

manufacturers in the United States to assist you in making informed decisions.

1. TrafFix

Devices: TrafFix Devices is a leading

manufacturer known for its innovative safety barrier solutions. With a focus on

quality and durability, their products are designed to meet the highest safety

standards.

2. Lindsay

Corporation: Lindsay Corporation is a trusted name

in the industry, offering a wide range of safety barriers that are designed to

provide maximum protection. Their commitment to safety and reliability sets

them apart.

3. Trinity

Highway: Trinity Highway is another prominent

manufacturer that specializes in safety barrier systems for various

applications. Their products are known for their superior quality and

performance.

4. Valmont

Industries: Valmont Industries is a

well-established manufacturer with a reputation for producing high-quality

safety barriers that are built to last. Their products are designed to

withstand the most demanding environments.

5. Barrier

Systems: Barrier Systems is a reliable

manufacturer that offers a comprehensive range of safety barrier solutions.

Their products are known for their effectiveness in enhancing safety and

security.

6. Tensar

International Corporation: Tensar

International Corporation is a global leader in the manufacture of safety

barriers and other infrastructure solutions. Their innovative products are

designed to provide superior protection in diverse settings.

7. Trinity

Industries: Trinity Industries is a respected

manufacturer that specializes in the production of safety barriers for roads,

highways, and industrial facilities. Their commitment to quality and safety is

evident in their products.

8. Gregory

Industries: Gregory Industries is a well-known

manufacturer that offers a diverse range of safety barrier products. Their

solutions are designed to meet the specific needs of different environments,

ensuring optimal protection.

9. A-Safe:

A-Safe is a leading manufacturer of polymer safety barriers that are designed

to provide exceptional protection in industrial settings. Their products are

known for their durability and reliability.

10. Ingal

Civil Products: Ingal Civil Products is a trusted

manufacturer that specializes in safety barrier systems for road and highway

applications. Their products are designed to meet the highest safety standards,

making them a top choice for reliable protection.

When

choosing a safety barrier product, it is essential to consider the reputation

and track record of the manufacturer. By selecting a reliable safety barrier suppliers, you

can ensure that you are investing in a high-quality product that will

effectively enhance safety and security in your environment. The manufacturers

mentioned in this guide are known for their commitment to excellence and their

ability to deliver top-notch safety barrier solutions. By exploring their

products and services, you can make an informed decision that will help

safeguard your surroundings and protect against potential hazards.

En el mundo del

embalaje, la eficiencia, la rentabilidad y la funcionalidad son factores clave

que todo fabricante tiene en cuenta. La BM2508-SE es un fabricante líder de

máquinas multifuncionales Máquina

de caja corrugada para cajas de cartón ondulado, que ofrece una

solución totalmente automática con ranurado y marcado horizontal, corte y

plegado vertical y corte horizontal, todo ello dentro de una máquina compacta.

El modelo BM2508-SE destaca por ser una versión económica en comparación con la

BM2508-Plus, lo que la convierte en una opción crucial para los usuarios en

estos tiempos difíciles, como la actual epidemia.

Una de las principales ventajas del modelo BM2508-SE es su capacidad para ofrecer soluciones rentables sin comprometer la calidad ni la funcionalidad. Al equipar la máquina con un alimentador de bordes delantero de 900 mm, 2 ruedas de hendido verticales y un módulo de perforación de agujeros de extracción manual, la BM2508-SE garantiza que los usuarios puedan agilizar sus procesos de fabricación de cajas manteniendo los costes bajo control. Este diseño estratégico no sólo reduce la inversión inicial, sino que también minimiza los gastos operativos, lo que la convierte en una opción sostenible para empresas de todos los tamaños.

La inclusión de un

alimentador de borde delantero con una longitud considerable de 900 mm mejora

la eficiencia de la máquina al permitir una alimentación sin interrupciones de

las planchas de cartón ondulado. Esta característica es especialmente beneficiosa

para situaciones de producción de gran volumen en las que el funcionamiento

continuo es esencial. Además, las 2 ruedas de hendido verticales desempeñan un

papel fundamental a la hora de garantizar un plegado y hendido precisos del

material ondulado, lo que se traduce en estructuras de caja bien definidas y

uniformes. Este nivel de precisión es crucial para ofrecer soluciones de

envasado de alta calidad que cumplan los estándares del sector y las

expectativas de los clientes.

Además, el módulo

de perforación de agujeros extraído manualmente añade versatilidad a la máquina

BM2508-SE, permitiendo a los usuarios personalizar los diseños de sus cajas con

facilidad. Tanto si se trata de crear orificios para asas, perforaciones de ventilación

u otros recortes especializados, esta función permite a los fabricantes

satisfacer diversos requisitos de envasado sin necesidad de ajustes complejos

ni equipos adicionales. Esta flexibilidad es una ventaja significativa para las

empresas que buscan ofrecer soluciones de envasado únicas y personalizadas a

sus clientes.

Además de sus

capacidades funcionales, el modelo BM2508-SE está diseñado para optimizar el

uso del espacio, por lo que es ideal para instalaciones de fabricación con

espacio limitado. El tamaño compacto de la máquina permite integrarla

perfectamente en las líneas de producción existentes o utilizarla como unidad

independiente, lo que proporciona a las empresas la flexibilidad necesaria para

adaptarse a las cambiantes necesidades de producción. Esta escalabilidad es

esencial para las empresas que buscan mejorar sus capacidades de fabricación

sin realizar grandes inversiones en infraestructuras.

En conclusión, el

modelo BM2508-SE representa un paso hacia la fabricación de cajas sostenible y

eficiente, atendiendo a las necesidades cambiantes de la industria. Con su

diseño económico, sus funciones versátiles y su tamaño compacto, esta máquina

establece un nuevo estándar para soluciones de envasado rentables. A medida que

las empresas tratan de superar los retos y aprovechar las oportunidades en el

entorno empresarial actual, la BM2508-SE destaca como un socio fiable para

impulsar el crecimiento y el éxito en la industria del envasado.

The Low Voltage Motor Control Center (MCC) is an essential component in industrial and

commercial settings, providing a centralized solution for controlling and

protecting motors. This integrated electrical control equipment plays a crucial

role in ensuring the efficient and safe operation of motors in a wide range of

applications.

At the heart of the

low voltage MCC is its robust and durable frame, which serves as the structural

backbone of the system. The frame is designed to support the various components

of the MCC, providing a secure and reliable enclosure for the electrical equipment

within. This sturdy construction ensures the safe operation of the MCC even in

demanding industrial environments.

Busbars are another

key element of the low voltage MCC, responsible for distributing power to the

connected motors. These conductive bars serve as the main power distribution

network within the MCC, efficiently delivering electricity to the various components

and ensuring smooth and reliable operation. The busbars are designed to handle

the electrical load required by the motors, providing a stable and consistent

power supply.

Circuit breakers

are integral to the functionality of the low voltage MCC, serving as the

primary means of protection against electrical faults and overloads. These

devices are designed to interrupt the flow of electricity in the event of a

fault, preventing damage to the motors and other components of the system. By

quickly isolating the faulty circuit, circuit breakers help to maintain the

safety and integrity of the electrical system.

Starters are

another critical component of the low voltage MCC, responsible for initiating

the operation of the connected motors. These devices provide the necessary

power and control signals to start and stop the motors as required, enabling

precise and efficient operation. Starters are equipped with various control

features to ensure smooth and reliable motor performance, enhancing the overall

efficiency of the system.

Control devices

play a vital role in the low voltage MCC, allowing operators to monitor and

adjust the operation of the motors as needed. These devices provide a

user-friendly interface for controlling the speed, direction, and other

parameters of the motors, enabling precise and customized operation. Control

devices help operators to optimize the performance of the motors, increasing

productivity and reducing downtime.

Interlocking

devices are essential safety features in the low voltage MCC, designed to

prevent hazardous operating conditions. These devices ensure that certain

operations can only be performed in a specific sequence, reducing the risk of

accidents and damage. Interlocking devices help to maintain a safe working

environment and protect both the equipment and personnel from harm.

In

conclusion, the lLow Voltage Motor Control Center is a versatile and reliable

solution for controlling and protecting motors in industrial and commercial

applications. With its integrated design and comprehensive features, the low

voltage MCC provides centralized control and power distribution, enhancing the

efficiency and safety of motor operations. By incorporating a robust frame,

busbars, circuit breakers, starters, control devices, interlocking devices, and

cable ducts, the low voltage MCC offers a complete and effective solution for

motor control requirements.

Linkotest,

a leading provider of testing equipment, offers state-of-the-art PC-controlled

pneumatic shock testers known as Bump Test Machine These machines are

meticulously designed to deliver precise and consistent shock testing results,

making them ideal for both laboratory research and production line quality

control applications. With the capability to test samples weighing up to 1000

kg, depending on the model, Linkotest's Bump Test Machines are versatile and

reliable tools for a wide range of industries.

One

of the key features that set Linkotest's Bump Test Machines apart is their

shock pulse programming capability. Equipped with advanced shock pulse

programmers, these machines can generate short and long duration half sine

shock pulses with exceptional accuracy. This functionality enables them to meet

stringent automotive, military, and industrial testing standards, as well as

accommodate customized testing requirements with ease. The generated waveforms

adhere to various military standards, including MIL-STD-202, MIL-STD-750,

MIL-STD-810, and MIL-STD-883, ensuring compliance and reliability in testing

procedures.

The

fundamental purpose of Linkotest's Bump Test Machines is to replicate the

effects of repeated bumps that components and equipment may encounter during

transportation or when installed in various vehicles. By subjecting samples to

controlled shock pulses, these machines simulate real-world bump conditions,

allowing manufacturers to assess the durability and performance of their

products under challenging circumstances. Mounted on an air spring and equipped

with heavy shock absorbers, Linkotest's Bump Test Machines effectively isolate

themselves from the ground, ensuring stability and reliability throughout the

testing process.

The

design of Linkotest's Bump Test Machines not only guarantees accurate

simulation of bump conditions but also prioritizes user safety and equipment

longevity. By incorporating robust materials and precision engineering, these

machines offer unparalleled durability and performance, making them a valuable

investment for businesses seeking to enhance their product testing

capabilities. Whether testing electronic components, automotive parts, or

industrial machinery, Linkotest's Bump Test Machines deliver consistent and

reliable results, helping companies improve the quality and reliability of

their products.

In

conclusion, Linkotest's Bump Test Machines represent a cutting-edge solution

for accurate and repeatable shock testing in diverse industries. With their

advanced shock pulse programming capabilities, compliance with military

standards, and robust design features, these machines offer a reliable and

efficient way to assess the impact resistance of products under various

conditions. By investing in Linkotest's Bump Test Machines, businesses can

streamline their testing processes, enhance product quality, and ultimately

gain a competitive edge in the market.

With over a decade

of experience in the packaging tubes for electronicsindustry, Hopak

has established itself as a leading manufacturer of cylinder packaging,

specializing in custom electronic packaging using high-quality paper tubes.

Whether you are in the business of selling electronics or electronic parts,

Hopak's electronic tube packaging is designed to enhance the value of your

brand and provide a premium packaging solution for your products.

What sets Hopak

apart from other suppliers is its unwavering commitment to using only the

finest first-class paper materials for its packaging. This dedication ensures

that your delicate electronic products are protected from scratches and other damage,

offering a secure and reliable packaging solution that reflects the

sophistication of your technology.

At Hopak, we

understand the importance of creating packaging that is not only functional but

also visually appealing. Our team of experts works diligently to craft

electronic packaging solutions that not only safeguard your products but also

showcase the advanced technology within. By combining innovative design with

high-quality materials, we strive to deliver packaging that not only protects

your products but also elevates the overall presentation of your brand.

One of the key

features of our electronic packaging is the use of custom inserts, such as EVA

foam or cardboard, to securely hold your products in place. These inserts are

designed to provide a snug fit for your items, ensuring that they remain

damage-free during transit and storage. Additionally, these inserts are perfect

for displaying your products, allowing customers to get a clear view of the

item while keeping it always protected.

When it comes to

printing, Hopak utilizes state-of-the-art digital and offset presses to ensure

that every detail of your packaging is of the highest quality. Whether you

require intricate designs, vibrant colors, or custom branding, our printing

capabilities are tailored to meet your specific needs. This attention to detail

and precision in printing allows us to create packaging that not only protects

your products but also enhances the overall aesthetic appeal of your brand.

If you are in

search of a reliable supplier for custom electronic packaging, look no further

than Hopak. Our team of experienced professionals provides you with the most

suitable electronic packaging solutions that meet your unique requirements.

From concept to creation, we work closely with our clients to ensure that their

packaging needs are met with precision and care, delivering a final product that

exceeds expectations.

In

conclusion, Hopak's custom electronic packaging offers a combination of

quality, functionality, and visual appeal that is unmatched in the packaging tubes for

electronicsindustry. With a focus on using premium

materials, innovative design, and high-quality printing, we are committed to

providing our clients with packaging solutions that not only protect their

products but also elevate their brand presence. Trust in Hopak for all your packaging tubes for electronicsneeds and experience the difference that

quality packaging can make for your products and your brand.

Aotons Kick Rail is a versatile

safety solution designed to prevent forklift trucks from passing through and

colliding from the bottom. These robust rails serve multiple purposes,

including acting as ground pallet storage, limiting forklift truck movement,

and integrating into traffic or pedestrian safety barriers. Tested for

durability and strength, Aotons kick rails have been proven to withstand

significant impact forces.

One of the primary

functions of Aotons kick rails is to act as a barrier that restricts the

movement of forklift trucks, thereby reducing the risk of accidents and

collisions in industrial settings. By strategically placing these rails in key

locations, businesses can effectively control the flow of traffic and enhance

overall safety measures within their facilities.

Moreover, Aotons

kick rails can also serve as a practical storage solution for pallets,

optimizing space utilization and ensuring efficient warehouse operations. By

utilizing these rails as ground pallet storage, businesses can streamline their

inventory management processes and create a more organized and structured

storage environment.

In addition to

their role in preventing forklift truck collisions and facilitating pallet

storage, Aotons kick rails can be seamlessly integrated into existing traffic

or pedestrian safety barrier systems. This adaptability allows businesses to

enhance the overall safety infrastructure of their premises and create a

comprehensive safety network that addresses various potential hazards.

A notable feature

of Aotons kick rails is their exceptional durability and impact resistance.

Through rigorous impact testing, these kick rails have demonstrated the ability

to withstand the force of a 6-ton forklift truck traveling at a speed of 5km/h

without sustaining any damage. This impressive level of resilience ensures that

Aotons kick rails can effectively protect against high-impact incidents and

maintain their structural integrity over time.

The robust

construction and reliable performance of Aotons kick rails make them a valuable

safety investment for businesses across various industries. Whether used as a

standalone safety measure or integrated into a broader safety system, these

kick rails provide a reliable solution for enhancing workplace safety and

mitigating the risks associated with forklift truck operations.

In conclusion, Aotons Kick Rail offer a

versatile and effective safety solution for preventing forklift truck

collisions, facilitating pallet storage, and enhancing overall safety measures

in industrial environments. With their proven durability, impact resistance,

and adaptability, these kick rails are an asset for businesses looking to

prioritize safety and optimize their operational efficiency.

.jpg)

.jpg)

.jpg)

.jpg)