fannyzeng's blog

Special paper is made from different fibers using a paper machine to produce paper with special functions. For example, raw materials such as synthetic fibers, synthetic pulp, or mixed wood pulp are used separately. And modified or processed with different materials to endow the paper with different functions and purposes.

Due to the wide variety and varying design effects. The following will only introduce the applications of several commonly used in printing special papers.

1. Plant parchment (sulfuric acid paper)

Because it is a semi transparent paper, sulfuric acid paper is often used as a ring lining or backing paper for books in modern design. Which can better highlight and set off the theme, while also in line with modern trends. Sometimes used as the title page of a book or picture album. Printing gold, silver, or graphics on sulfuric acid paper is unique and commonly used in high-end art albums.

It is also used for sulfuric acid paper in the production of architectural drawings and early printing and assembly of transfer media paper.

2. Synthetic paper (polymer paper and plastic paper)

Generally, synthetic paper is divided into two categories: one is fiber based synthetic paper, and the other is film based synthetic paper.

Synthetic paper has little difference in appearance from ordinary natural plant fiber paper. Thin film synthetic paper has entered the market of high-end printing paper and can adapt to various printing machines. Synthetic paper has excellent printing performance and will not experience "paper breakage" during printing. The surface of synthetic paper exhibits extremely small concave and convex shapes, which greatly helps to improve opacity. Synthetic paper has good image reproduction, clear dots, soft tones, stable size, and is not prone to aging.

3. Texture paper

The production of embossed paper involves the use of mechanical embossing. Or wrinkling to form a concave and convex pattern on the surface of the paper or cardboard. Embossed paper enhances its decorative effect by embossing, making the paper more textured.

Embossing can be divided into two types: overprint embossing and non overprint embossing. The so-called overprint embossing refers to pressing the printed flower shape into a concave convex shape according to the printed pattern, making the pattern bulge, which can play a beautiful decorative role.

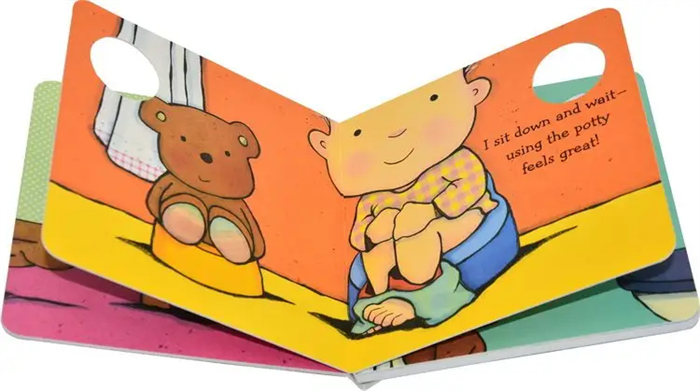

Most of the domestic embossed paper is made of offset paper and whiteboard paper. The surface is relatively rough, textured, expressive, and diverse. Many art designers prefer to use this type of paper when plan to do book cover printing, title pages, etc. to express different personalities. Such as hardcover children's book printing.

4. Patterned paper

Designers and printers constantly seek innovative design styles to make their works stand out. Many times, patterned paper can make them even more beautiful. This type of high-quality paper product has a soft hand feel, a beautiful appearance, and a more noble and pleasing finished product. There are many varieties of patterned paper with different characteristics, which are higher in grade than ordinary paper.

Book publishers also require more durable paper and prefer it to be fresh and firm to ensure stable and consistent printing results. The product designed with antique effect paper is simple, beautiful, and elegant.

The trend of environmental protection is on the rise, and spotted paper has emerged. In order to achieve the effect of natural regeneration, various impurities have been added to the pulp. Some environmentally friendly recycled paper contains impurities such as minerals, floating snow, petals, etc. Its manufacturing techniques include adding dyes in the sizing process to make the paper form spots or create the parchment effect. This type of paper is highly popular among consumers and is the preferred choice for various certificates, book covers, restaurant recipes, and beverage lists.

Metal "Star Collection" can be used to produce various high-end printed materials, such as paper used as product samples, covers for annual reports and books, and for various packaging boxes.

There is a qualitative difference between gold paper and traditional gold foil. Traditional gold foil can only be printed using transparent materials and cannot be directly colored for printing. The gold paper developed using 24K gold as the material and nano technology can not only print color images directly on gold, but also retain the charm and performance of gold. It has the characteristics of oxidation resistance, color resistance, moisture resistance, and moth resistance, avoiding the shortcomings of traditional paper and books that are prone to mold and insects. In theory, it can be stored for tens of thousands of years.

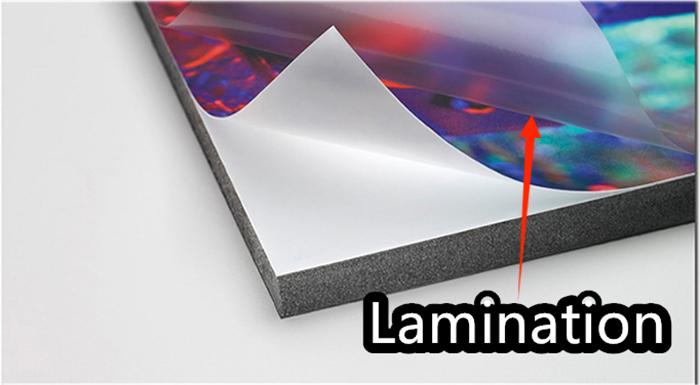

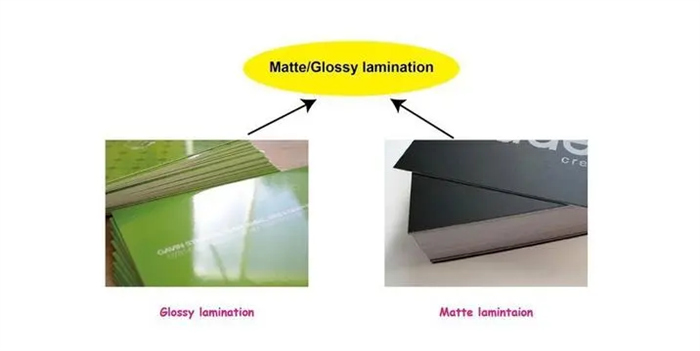

For printing children's books, lamination is an important step that can make a huge difference in the quality of the final product. But what is the difference between glossy and matte lamination? Which one is better for printing children's books? In this blog post, we will explore the differences between glossy and matte lamination.

What's glossy lamination

Glossy lamination is a type of print finishing which adds a glossy sheen to printed materials. It is typically used to enhance the visual appeal of book covers, postcards, business cards, and other types of printed material. Glossy lamination also provides protection from dirt and moisture as well as general wear and tear.

The glossy finish is created using a clear plastic film applied to the printed surface with heat and pressure. This process can be done either manually or with an automated machine. The film is heat-sealed onto the substrate, which creates a uniform bond between the two surfaces. It makes the material resistant to water, dust, and other environmental factors that could damage it over time.

The most common type of glossy lamination uses polypropylene (PP) or polyethylene terephthalate (PET) films. Both are extremely durable materials that provide superior protection against scratching, tearing and fading due to sunlight exposure. These films come in different thicknesses ranging from 25 microns (1 mil) up to 250 microns (10 mil). Thinner films are more flexible but less durable than thicker ones. However, they allow for sharper images when printing photos or graphics on book covers or other documents that require fine details in their artwork.

Glossy lamination offers many advantages over matte lamination. That includes increased vibrancy of colors and improved overall durability of the finished product. The glossy finish helps draw attention to the cover design while providing extra protection against abrasion, moisture and other environmental factors that can cause damage over time. It also reduces glare when viewing photographs or graphics in direct sunlight or bright light conditions.

What's matte lamination

Matt lamination is a coating process used in the print industry to protect and enhance the appearance of paper products. It involves applying a thin, transparent plastic film over the surface of the material. This film provides a matte finish that increases durability and reduces dirt and moisture absorption. While also offering protection from ultraviolet light. Also, Matt lamination helps to increase the vibrancy of printed colors on textiles and other materials, making them last longer.

The most common type of matt lamination is single-sided lamination. Where one side of an item is laminated with a matte finish while leaving the other side uncoated. Single-sided matte lamination can be applied to book covers, business cards, flyers, and brochures, as well as many other printed materials. Double-sided matt lamination (also known as 'double coating') covers both sides and adds an extra layer of protection for items. Such as posters or menus which are likely to face more wear and tear during their lifetime.

Matt laminates are available in various thicknesses depending on their intended purpose. Thinner films are suitable for applications. Such as book covers or postcards, that require flexibility but need minimal protection from external elements. Whereas thicker films offer greater protection from water damage or fingerprints for items. Such as menus or photographs that are likely to be handled often.

In terms of cost-effectiveness for businesses, who are looking for extra durability for their prints without sacrificing quality aesthetics, matt laminates provide an ideal solution. They are not only cost effective compared.

Overall matt lamination provides a matte finish that enhances color vibrancy while increasing durability. Making it an ideal choice for businesses looking to add value to their printed products without breaking the bank.

Why need to laminate when printing children's book

When printing children's books, lamination is a must. Not only does it help protect the book from wear and tear. But it can also add an extra layer of durability and beauty to the design. Lamination provides a glossy finish that makes colors pop. While also making the cover more resistant to dirt and moisture. It also helps prevent fading over time, so your child's favorite stories will remain vibrant for years to come.

But there's more to lamination than just enhancing aesthetics. It can also provide protection against damage from spills or everyday use. In fact, Matt lamination is better suited for protecting children's books. Because it provides a matte finish that resists fingerprints and smudges better than glossy lamination does. Plus, Matt lamination tends to be slightly thicker than glossy lamination – perfect for thicker paper stock. Such as those found in children's books – providing an even greater level of protection without sacrificing design elements like color vibrancy or texture.

Overall, when custom children's book printing, matt or glossy lamination offers a range of benefits. That makes them worth considering no matter what your budget may be. Not only will they keep your printed products looking great while helping them last longer and resist wear and tear. But they can also bring out the best possible features in your designs so you get the most out of each page turn!

The benefits of lamination for children's book printing

Lamination is an ideal choice for children's books, providing a range of benefits that make them look great and last longer. The glossy or matte finish of lamination helps to enhance the vibrancy of the colors and makes them pop off the page. It gives printed products a professional and polished appearance. Also making them more attractive to potential customers. Lamination also protects against fading, making sure that the colors stay vibrant for years to come.

Besides, matt lamination offers superior protection for children's books compared to glossy lamination due to its thicker paper stock. This provides extra durability and helps prevent wear and tear from handling. Which can be especially important with frequently handled items such as children's books. Additionally, matt lamination can provide more cost-effectiveness compared to other coating processes such as varnishes or UV coatings.

Overall, both matte and glossy laminates offer many benefits for book printing. Helps to protect against dirt and moisture absorption while keeping printing costs down due to improved longevity. Matt lamination is particularly suited for protecting children's books due to its thicker paper stock. And matte finish, which adds an extra layer of durability without compromising on color vibrancy or longevity. Ultimately, it provides a beautiful glossy or matte finish that enhances color vibrancy while increasing durability. Making it an ideal choice when printing books intended for young readers, such as custom board book for babies.

Glossy VS matt lamination: which is better for children's book

When printing children's books, there are two main types of lamination available: glossy and Matt. It is important to consider which finish is best suited for the project when deciding on what type of lamination to use. Both glossy and Matt lamination have their own advantages, making them suitable for different kinds of projects.

Glossy lamination provides a beautiful high-gloss finish. That enhances color vibrancy while protecting against dirt and moisture absorption. It is ideal for projects such as book covers or posters that require an eye-catching look and feel. However, glossy lamination doesn't provide enough protection from wear and tear over time. So it isn't always the most suitable choice for children's books that need to stand up to repeated handling.

Matt lamination offers superior protection against wear and tear due to its thicker paper stock. Making it an ideal choice for children's books that need extra durability. The matte finish also helps keep colors vibrant and prevents fading over time, giving the book a longer lifespan. Matt lamination can also be used on other materials. Such as business cards or flyers, allowing you to add an extra layer of protection without compromising on color vibrancy or longevity.

Ultimately, both glossy and Matt lamination offer their own unique benefits that make them worth considering depending on the project in question. Glossy laminates are perfect for items, such as book covers or posters that require an eye-catching look and feel. Matt laminate offers superior protection against wear and tear due to its thicker paper stock. Making it ideal for children's books that need extra durability.

Summary

In summary, lamination is essential when printing children's books. As it helps protect the book from wear and tear while enhancing color vibrancy. Both glossy and matt lamination offer a range of benefits that make them worth considering. Glossy lamination provides a beautiful high-gloss finish that enhances color vibrancy while protecting against dirt and moisture absorption, making it ideal for projects, such as book covers or posters.

Matt lamination, meanwhile, offers superior protection against wear and tear due to its thicker paper stock, making it an ideal choice for children's books that need extra durability. The matte finish also helps keep colors vibrant and prevents fading over time, giving the book a longer lifespan.

Ultimately, both glossy and matt lamination offer their own unique benefits that can help make any project look great and last longer.

Board books are a beloved staple in children's literature. Board books offer young readers a durable and interactive reading experience. When it comes to producing board books, choosing the right printing technique is essential to ensure a high-quality and long-lasting product. In this article, we will explore the different printing options available for board books and delve into their respective benefits.

Offset printing is a widely used technique in the printing industry. Due to its versatility and ability to produce crisp and vibrant images. This method involves transferring ink from metal plates to a rubber blanket. Which then transfers the ink to the printing surface, typically paper or board stock. Compared to other printing methods, offset printing delivers excellent color accuracy, sharp details, and high-quality resolution.

For board books, offset printing is an ideal choice for achieving vivid illustrations and complex designs. The method's ability to accurately replicate intricate artwork. It ensures that the visuals on each page are captivating and engaging for young readers. Offset printing is also suitable for printing large quantities, making it a cost-effective option for mass production.

Digital Printing:

Digital printing has gained popularity in recent years due to its speed, affordability, and flexibility. Unlike offset printing, digital printing does not need to make plates. That making it a more straightforward and efficient process. This method involves transferring the digital image directly onto the desired printing surface through electronic data.

Digital printing is well-suited for short to medium print runs and offers quick turnaround times. It allows for on-demand printing, which is particularly beneficial for publishers. Or authors who require small quantities or personalized board books. Additionally, digital printing offers excellent color accuracy. It also can reproduce vibrant illustrations and photographs.

Screen Printing:

Screen printing, also known as silk screening. It is a versatile printing technique that involves pushing ink through a mesh screen onto the printing surface. Each color requires a separate screen, allowing for precise color layering and vibrant visuals. Screen printing is commonly used for printing on uneven or specialty materials like board stock.

Screen printing is suitable for board books that require bold and solid colors without intricate details. This method offers excellent opacity and durability. That making it a preferred choice for board books that undergo rigorous handling by young readers. Screen printing can add texture and dimension to the illustrations, enhancing the tactile experience of the book.

UV Printing:

UV printing is a modern and advanced printing technique. That uses ultraviolet (UV) light to quickly cure the ink onto the printing surface. This process results in vibrant colors, excellent image sharpness, and enhanced durability. UV printing is commonly used on a variety of materials, including board stock.

For board books, UV printing offers several advantages. The cured ink is resistant to scratching and scuffing, making it ideal for books that will be handled by young children. UV printing also provides a glossy and smooth finish. Enhancing the overall aesthetic appeal of the illustrations and graphics on the board book pages.

Choosing the Right Printing Technique:

When selecting the appropriate printing technique for your board book, several factors should be considered:

Quantity:If you require a large print run, offset printing would be a cost-effective choice. For smaller quantities or personalized printing, digital printing might be more suitable.

Artwork Complexity:If your board book contains intricate illustrations or photographs. Offset printing can reproduce them with precision. For solid colors or simple designs, screen printing or UV printing can provide the desired effect.

Budget:Consider your budget constraints and compare the costs associated with each printing technique. Offset printing usually more cost-effective for large print runs. While digital printing may be more economical for smaller quantities.

Timeframe:Assess your printing timeline. Digital printing offers quick turnaround times. While offset printing may require more lead time due to setup and production processes.

Conclusion:

Selecting the appropriate printing technique is vital to the successful production of board books. Digital printing, offset printing, screen printing and UV printing. Each offer unique benefits depending on factors such as artwork complexity, quantity, budget, and timeframe. Understanding the strengths of each technique will enable you to make an informed decision. And ensure that your board book printing is visually appealing, durable, and engaging for young readers.